Building an Efficient Rice Processing Mill: A Complete Guide for Modern Millers

Rice is a cornerstone of global food consumption, feeding billions of people each day. With population growth and increasing demand for quality rice, the need for efficient processing solutions has never been greater. A Rice Processing Mill plays a central role in transforming raw paddy into polished, market-ready rice that meets both local and international standards. In this guide, we will explore how a rice processing mill works, its key components, benefits, and how to choose the right system to grow a profitable rice milling business.

What is a Rice Processing Mill?

A Rice Processing Mill is a facility equipped with machinery that performs a sequence of mechanical processes to convert harvested paddy into polished white rice. These processes include cleaning, husking, separating, whitening, polishing, grading, color sorting, and packing. Whether it’s a small-scale setup or a large industrial plant, the main objective of a rice processing mill is to maximize yield, maintain high grain quality, and ensure operational efficiency.

Why Rice Processing Mills Are Essential

Rice milling is more than just removing husk and bran. Modern rice processing mills are engineered to enhance the overall value of rice by delivering consistent quality, reducing waste, and increasing production capacity. Here’s why rice mills are indispensable in today’s agricultural sector:

High-Quality Output

Modern mills are capable of producing uniform, polished rice that meets commercial and export-grade standards. Advanced machinery ensures reduced broken grains and a shiny, appealing finish.

Labor Efficiency

Automation significantly reduces the reliance on manual labor. This allows mill owners to cut costs while improving consistency and speed.

Value Addition

By processing rice to higher standards, a rice mill increases the market value of the final product, especially in premium markets that demand clean, polished, and sorted rice.

Better Storage and Shelf Life

Processed rice, when cleaned and packed efficiently, lasts longer and is less prone to spoilage or pest infestation.

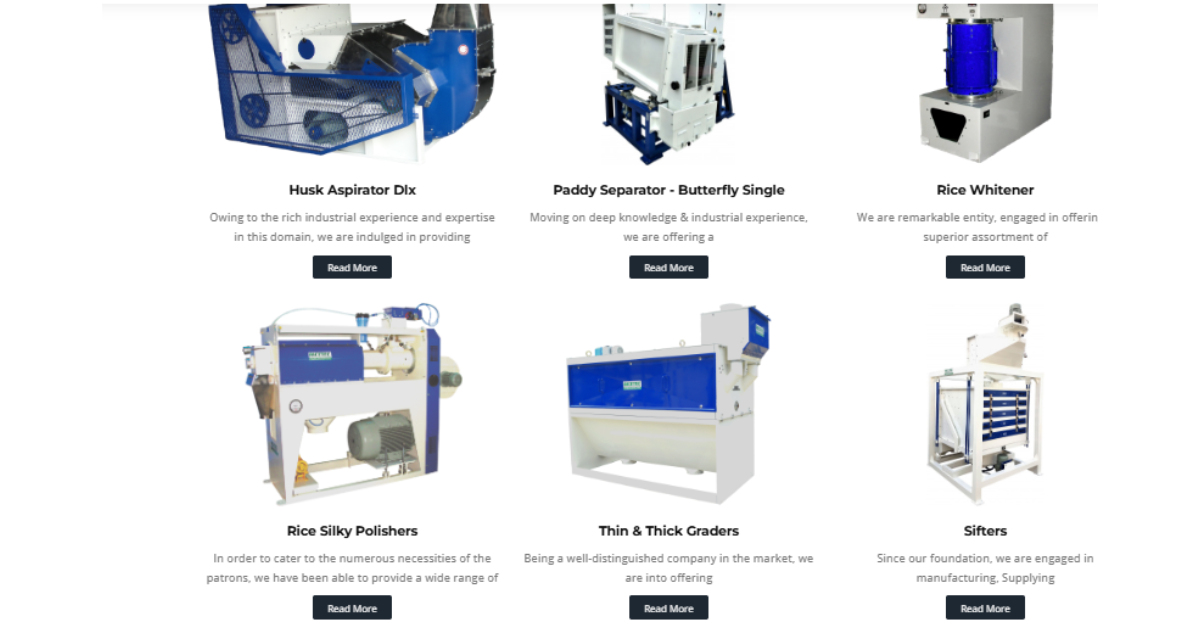

Key Components of a Rice Processing Mill

A fully functional rice processing mill includes various stages and corresponding machinery to ensure a smooth and efficient workflow:

Pre-Cleaning Equipment

Before any processing, paddy needs to be cleaned to remove dust, stones, straw, and other foreign materials. Vibratory sieves and destoners are commonly used in this stage.

Dehusking or Husking Machine

This machine removes the outer husk from the rice grain using rubber rollers or a frictional mechanism. The result is brown rice, which still has its bran layer intact.

Paddy Separator

After husking, a mixture of brown rice and unhusked paddy is formed. Paddy separators separate the unprocessed grains so they can be reprocessed.

Whitening Machine

The whitening process removes the bran layer from brown rice, producing white rice. This is usually done in multiple passes to prevent breakage and maintain uniformity.

Polishing Unit

Polishing gives the rice its final look by improving texture and enhancing the surface gloss. Mist or water polishing systems are often used for better results.

Grading Machine

Grading involves separating rice based on size and quality. This ensures only high-grade, uniformly sized grains make it to the market.

Color Sorting Machine

Advanced rice mills use color sorters equipped with optical sensors to detect and remove discolored or damaged grains, ensuring only premium rice is packaged.

Packaging System

Once the rice is processed and sorted, it is packed using automated systems. Packaging machines weigh, seal, and label bags for retail or bulk distribution.

Benefits of a Modern Rice Processing Mill

High Production Capacity

Modern mills can process tons of paddy in a day, ensuring timely delivery and helping millers meet growing market demands.

Consistency in Quality

Integrated systems and digital controls ensure uniform output regardless of input quality, maintaining customer satisfaction and brand trust.

Cost Efficiency

Automated processes reduce labor and energy costs, contributing to higher profit margins in the long run.

Hygiene and Food Safety

With stainless steel construction and enclosed systems, modern rice mills meet strict hygiene standards, essential for both domestic and export markets.

Environmental Sustainability

Newer models are designed to minimize energy consumption, reduce waste, and recycle by-products such as husk and bran for other uses like fuel or animal feed.

How to Set Up a Successful Rice Processing Mill

Setting up a rice processing mill involves several strategic steps, from selecting equipment to planning operations. Here are key considerations:

Define Your Capacity

Choose the size and scale of your rice mill based on daily processing needs. Whether you’re aiming for a small mill or an industrial plant, capacity planning is crucial.

Select the Right Machinery

Invest in machines that match your rice type and processing goals. Look for durable equipment with high efficiency and low maintenance requirements.

Layout and Infrastructure

Plan the mill layout for smooth workflow between different sections. Proper ventilation, power supply, and space allocation are important for operational efficiency.

Skilled Labor and Training

Even with automation, skilled workers are needed to monitor systems, handle maintenance, and ensure quality control. Choose a machinery supplier that offers training.

Compliance and Certification

Adhere to local food safety standards, environmental regulations, and obtain necessary certifications for both domestic and export markets.

Why Choose Ricetec Machinery for Your Rice Processing Mill

Ricetec Machinery is a leading provider of complete rice milling solutions, trusted by millers across India and globally. Here’s why Ricetec stands out:

-

Full-range product lineup from pre-cleaners to packaging

-

Customized solutions based on rice type and market requirements

-

Energy-efficient and automation-ready systems

-

Robust build quality with stainless steel components

-

Installation, training, and after-sales support from experienced professionals

Whether you’re starting a new mill or upgrading an existing one, Ricetec Machinery delivers equipment and expertise that ensures long-term success.

Maintenance Tips for a Rice Processing Mill

Maintaining a rice mill is critical to preserving its efficiency and lifespan. Here are some essential maintenance practices:

-

Clean machines daily to prevent buildup of bran, husk, and dust

-

Regularly inspect belts, motors, and moving parts for wear

-

Lubricate parts as per manufacturer’s guidelines

-

Calibrate grading and sorting machines for consistent results

-

Keep spare parts for quick replacements and avoid downtime

Frequently Asked Questions (FAQ)

What is a rice processing mill used for?

A rice processing mill transforms raw paddy into white rice through stages like cleaning, husking, polishing, and packaging.

How much does it cost to set up a rice processing mill?

The cost depends on capacity, automation level, and equipment quality. Small mills may require lower investment, while industrial mills involve significant capital.

Can one rice processing mill handle different types of rice?

Yes, most modern mills are versatile and can process basmati, long grain, short grain, and parboiled rice with appropriate machine settings.

How do I choose the right location for my rice mill?

Select a location close to paddy sources and with good transport access, adequate water and electricity supply, and compliance with zoning laws.

Does Ricetec Machinery provide installation and support?

Yes, Ricetec offers end-to-end services including machine installation, operator training, layout planning, and after-sales support.

Conclusion

A Rice Processing Mill is a vital asset in the global food supply chain. It turns harvested paddy into polished, high-quality rice that meets consumer expectations and market standards. With increasing demand and competition, modernizing your rice processing mill is no longer optional—it’s essential. Ricetec Machinery offers comprehensive milling solutions that combine precision, reliability, and performance. Whether you’re entering the industry or looking to scale, a well-planned and well-equipped rice mill is your path to success in the rice business